- CRYO PUMP CRYO PUMP

- SUPER TRAP SUPER TRAP

- REFRIGERATOR REFRIGERATOR

- LN2GENERATOR LN2 GENERATOR

- MAINTENANCE MAINTENANCE

- SUPPORT SUPPORT

- COMPANY COMPANY

- CAREERS CAREERS

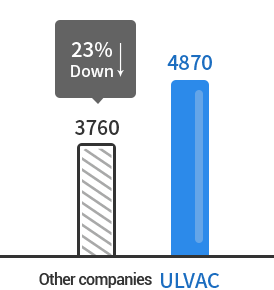

ULVAC CRYOGENICS KOREA INC recommends 16,000hr for 『CRYO PUMP』 and 24,000hr for Compressor with the lifespan of 3-4 years and 4-5 years for pump and compressor, respectively.

Failure to cool down the temperature (rise to the maximum cooling temperature and maintain it)

Failure to reduce the degree of vacuum (rise to the minimum degree of vacuum and maintain it)

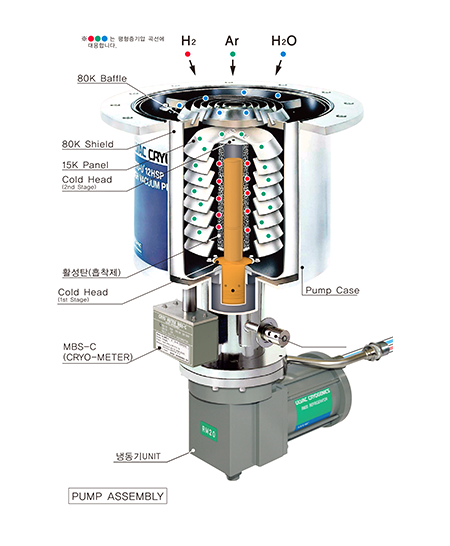

Sealing module ▶ Temperature searching (temperature is searched for and indicated with the mixture of helium in the first and second layers -> temperature rise up to 18-20K)

Bearing drive module ▶ Noise in bearing drive module (hammer-like sound at regular intervals)

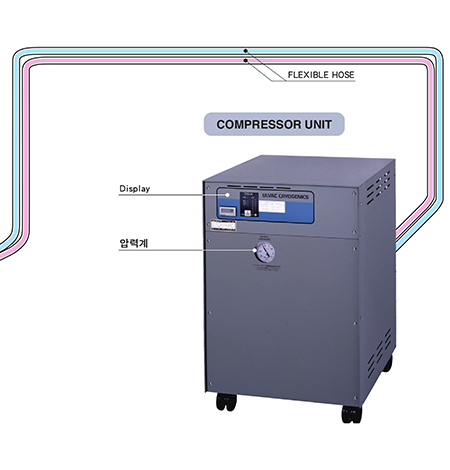

Return, Supply Valve ▶ No He movement sound (The movement of He does not go through a return-supply circulation.)

ULVAC CRYOGENICS KOREA INC provides our customers with regular inspection services, quick responses to your inquiries through our local branches nationwide and free-of-charge education & training programs as well.

Compressor → failure of activation (due to wear and tear of bearing inside the He compressor)

Internal parts of control box → failure of activation (due to expiration of operational life of the boards of electronic control parts on top of the compressor)

※ We also provide user manuals and in-house training services to allow our customers to properly respond to various unplanned events.

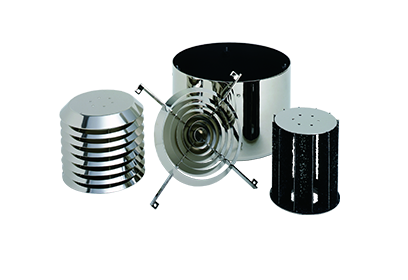

Enhanced product reliability by performing overhaul under the same conditions as for new products

Quality overhaul based on extensive production know-how of various models of CRYO PUMP

Regular inspection and calibration of MBS-C thermometer to promote the reliability of temperature measurement

Inspection, repair, and sales of various types of heaters and thermometers will be available to meet various customer needs

Overhaul product management with the same specifications as with regard to new products → enhances cooling performance and extends overhaul life

With an aim to provide better repair services, the extended building B of RMC will be used to achieve customer satisfaction through product management that is identical to the one for new products and will allow for a reduction in repair time.

Superior technical skills on CRYO PUMP through training at Japan HQ and years of experience and know-how

We provide assistance to facilitate a quick conversion to mass-production by detecting potential issues and problems in the early stage of set-up

We perform periodic inspections to identify potential problems in the initial stage so that customers are able to concentrate on core production activities only.

Minimizes delay through quick Services mobilized by our CS branches at home and abroad

We provide technical advice on renovation and exhaust capacity upgrade upon the request of customers

Parts Replacement

Parts Replacement

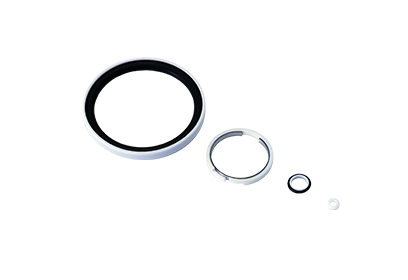

Inner KIT

Seal KIT

Bearing KIT

Adsorber